THE BEGINNING Brief History of the current Dam Repair Project

The earlier dates noted were from memory so they may not be exact. As time allows, we will attempt to get more precise dates.

In 2009, New York State Department of Environmental Conservation (DEC) enacted the Dam Safety Regulations requiring dams to be inspected, assigned a hazardous condition A-C, C considered a High Hazard, and require the owner to set up inspections and repair deficiencies. In the regulations, DEC was granted authority to force the dam owner to be breach the dam if they refused to complete repairs. This would have eliminated DeRuyter Reservoir forever. We would have had a nice golf course though.

DeRuyter, as well as most in Madison County Reservoirs and over 400 in the State were classified C. Fortunately, since 1989 the Lake Association established a good working relationship with the Canal Corporation (CC) through some long hard work by Bill Orzell. This relationship has continued through the years and was instrumental in getting the State to commit funds and select DeRuyter to be their first one to get repairs done costing millions.

The Association was extremely smart to change the way they dealt with the Canal Corporation. Rather than having negative mail and phone call campaigns against Canal Corporation employees trying to get them fired by involving politicians, the Lake Association passed a resolution to have a liaison person be the sole contact with the state to discuss our wishes in a collegial manner and all complaints would go to the Lake Association member and not the state. This built up a tremendous amount of trust through the years. That was a significant factor in the selection of DeRuyter.

The Canal Corporation carried out a prior 3 year project starting in 1989. That repair project pictures and explanation can be seen by clicking on the button at the end of this page entitled Dam Repair 1989 - 1991.

Through the years the southern Reservoirs were costly to maintain.

The Canal Corporation was transferred to the New York State Thruway Authority due their budget being in better shape to absorb the costs. The Thruway put additional staff on and started allocating money to inspect and maintain the Reservoirs. Over time, the Thruway Authority didn’t get the added revenues through a toll increase so the Reservoirs became a burden on them.

Serious discussion to decide which Reservoir would be the first one for the Canal Corporation to expend funds to bring into compliance went on for about a year following review of the initial Bergmann study. Most of the “Southern Reservoirs” needed some repairs but there wasn’t the money or staff to do all Reservoirs at once. In 2012, the CC received the preliminary assessments of the deficiencies of the Southern Reservoirs.

After some long discussions and with the great rapport the Association developed with the Canal Corporation through the years, they felt DeRuyter would be a good candidate to repair first. So a more detailed study continued with core sampling and piezometer installation in 2012. A preliminary design was completed including cost estimates.

The Canal Corporation received the budgeting from the NY Power Authority to complete a full design, develop bid specs, competitively bid the project and the project was awarded in August 2019 which included a very fast project schedule.

First and most important was the Reservoir had to be dropped 10 feet before work could start. To that end, the Association voted to allow the CC to drop the level one foot through August which proved a good decision. The Reservoir level reached close to the 10 foot drop mark by the end of September which was aided by a very dry rain free September. This allowed the contractor to mobilize the first week of October and they got a great jump on the project. The following pictures document some of the work being performed in mostly chronological order. This will be updated as work proceeds.

Click on link below to see the Canal Corporations original design slide show they used at their public information meetings.

An interesting observation, their computer generated view of what the 10 foot drop would look like is amazingly close to what it actually is.

Click Here for State Design Dam Project Slideshow.

T

The top picture shows some interesting items. First, the right half of the picture shows the Eastern Buttress area and the left shows the partial view of the Western Buttress which extends toward the overflow spillway not shown.

1 - Dam Rd Cutout where the two 22 inch siphon pipes will go through dam

2- Stone slab facing removed from dam have been number to be reinstalled in the exact place they were once the dam cut is filled in.

3- Pad for new upper level valve house

4- 22 inch siphon pipe and fusing machine

5- Eastern Buttress partial graded readied for collection pipe and manhole installation. Not the final grade level.

6- Current original valve house to be abandoned once Siphon system is completed and working. Valve house to be filled with sand, original inlet pipes into the water to be sealed and grouted. The buried concrete spillway exiting the valve house will also be abandoned down to the new Lower Level Valve House.

7- Compacted soil for New Lower Level Valve House. The L shape is where the stilling well outside the valve house will be installed. The top half will contain the discharge siphon control valves.

8- A weir box with flow monitoring will be installed to collect some of the seepage from the lower part of the western buttress and discharge into the federal wetland.

9- Lower access road to be installed for access to lower valve house.

10- Upper access road for upper valve house to be built after collection pipes and manholes are installed and backfill brought in to bring up grade.

Spillway bend showing drainage pipes that are under the full length of the spillway within the confines of the old spillway. The 2 pipes run the full length and are perforated to collect ground water underneath the spillway floor to maintain stability. You can see the old spillway thickness, about 10 inches thick, cut out for new collection pipes.

Then stone is filled across the whole floor/base

This shows the 40 foot deep sections of sheet pile driven in at the base of the first drop after the bend to stabilize this part of the spillway.

You can see the floor of the old spillway is about 10 to 12 inches thick.

There will be another set of sheet piles driven at the base of the last drop also to stabilize that section being reconstructed.

At the lowest part a large amount of revetment (stone

Looking north from dam road, this is the new overflow spillway being formed within the confines of the original spillway.

A lot of rebar is being used to make the concrete strong. The individual pads are being poured so joints can be installed between the sections. Much like the thruway has expansion joints built in that cause the thump thump thump you hear.

Under this rebar is new sand/stone with 2

Looking east across the Dam Rd Cut. Shown is the base form for the Upper Valve House that will have the two main 22 inch siphon valves and a 8 inch valve for normal continuous flow to the Limestone per DEC regulations, filling and venting piping and a dry hydrant for need to pump water should the siphon prime is lost.

In the distance you can see the Eastern Buttress graded. New manholes and colle

Shown is the Dam Cut where the new 22 inch Siphon Pipes will be installed prior to being covered.

To the left is the valve house floor form.

To the right you can see a temporary coffer dam built out of sand bags for safety.

On the road you can see the dam stone facing that was removed and numbered so it goes back in the same place.

Most of the waterside work including much under water work will be

Looking East on Dam Road

This shows the 22 inch pipe sections fused to make one long length of pipe.

These lengths will be used to go through Dam under Dam Rd. to allow for the drawdown of the Reservoir and meet NYS Dam Safety Regulations.

Individual pipes sections stacked on the right. 11-1-19

Bad News Good News

This fusing machine broke down the first week of November and it is the only one in NY State.

The Good news, the contractor was able to get it repaired and is continuing to complete the Siphon Pipe fusing so the pipes can be put down and covered and the Dam Rd. cut can be filled to grade of road.

Close Up of Fused Joint

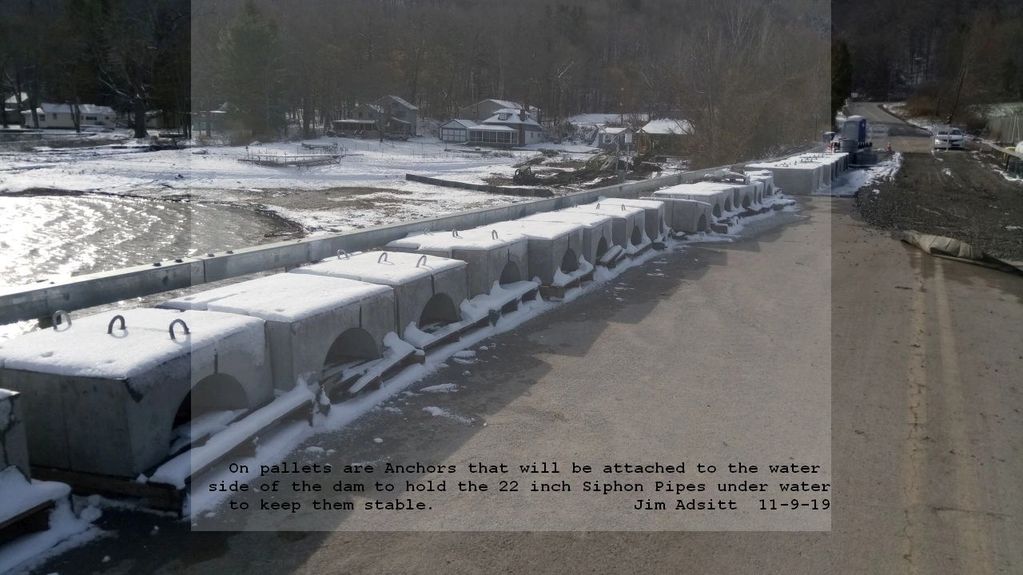

These concrete blocks will be used to anchor the 22 inch Siphon Pipes down along the face of the dam to the bottom to keep it from moving, floating, and stable.

Both Pipe Anchors and Buoy Anchors on the right waiting to be installed in the spring/summer of 2020

These concrete blocks will be used to anchor the large can buoys to be installed over the Siphon Pipe Location and one at the Outfall Spillway. These will be installed in the spring/summer of 2020.

The two manholes are set on the western buttress to grade. The eventual fill will be to almost the top of the manholes once collection pipes are installed. Possibly could be done this year but not a high priority.

Top right is the framed upper valve house ready for concrete pour scheduled this week or next.

In distance is the eastern buttress graded as high for this year. Also a manhole can be seen.

New Low Level Valve House Floor has been poured. The closet part, will be the siphon discharge valves room.

The farther section will be the stilling well that will discharge into a refurbished outlet channel filled with revetment/stone to stop scouring of the bottom of the channel.

New piezometer installed at the northern most part of the western buttress. This is at the base where the flow will be continuously monitored through a weir box to be installed before discharge into the Federal Wetland through a bunch of revetment (stone) acting as an energy dissipator.

The stone at top right is just a tempory check dam to slow any flow during winter and spring.

Standing at the base of the western buttress looking west up where current surface flow and some dam seepage flow comes down into the Federal Wetland.

There will be a weir box installed at this point to continuously measure flow coming from part of the western buttress. At the point of discharge there will be revetment(stone) installed as an energy dissipator.

There are other sections/areas that

Overflow Spillway Concrete Work Continues. Floor/base of upper spillway poured and work on the bend and lower part work progress as of 11-23-19.

Looking west at partial grade of eastern embankment. Collection pipes installed and new and raised manholes shown. Final grade will be brought up to manhole tops in 2020.

Looking west from middle of dam at western buttress showing some earth work equipment, beginnings of new entrance and access roads as of 11-23-19.

Work will progress slowly depending on weather conditions and temperatures. New fill brought in can't be compacted to specifications if to wet or frozen. Final grade, manholes, collection pipes and access roads to be completed in 2020.

22 inch Siphon Pipes. On right, 1 of 2 pipes have the anchor blocks attached. This will go into the water side of the dam to the bottom where it will be put into a trash rack. Water side work scheduled for spring/summer 2020.

Long sections on the left will be used for 2nd water side intake and the remainder will be used to run from upper valve house to lower valve house currently under construction

11-23-19 East Side of Dam Road with Temporary Turn Around. Madison County Highway requested this area for their snowplows because Dam Rd is closed. Thinking now is at completion of project, the guardrails will be replaced so it can't be used by the public but available for use by the State at a future date.

Also on left is the partial eastern embankment tarped. The purpose of this is to keep it fr

11-23-19 R Upper Valve House Inside Concrete Form in place.

Looking Southeast from Dam Road Cut

Two 22 inch Siphon Pipes and 8 inch Primer Pipe installed 2nd/3rd Week of December 2019.

Workers heating ground to insure proper compaction of cold soil.

Photo provided by NYS Canal Corporation.

Looking Southeast from Dam Road Cut

Siphon Pipes and smaller 8 inch Priming/Dry Hydrant Pipe installed and soil being compacted by Articulating Trench Roller/Compactor (manufacturer video)

The whitish/gray material on left side of picture is a granular bentonite mix which extends 3 feet on all sides of the pipes. When this material gets wet, it swells and seals the pipe to prevent water from runni

December 29, 2019

Two 22 inch and one 8 inch pipe installed through the dam. These pipes are covered by granular bentonite mix under and around circumference of the pipes and extends 3 feet on all sides and a layer on top and bottom. Water proof sheet material is applied over the top for protection and then compacted soil will be added to bring elevation up to the dam road height eventually.

Check valves and the

One of two 22 inch siphon pipe strings fused into one pipe to be installed in spring/summer with anchor blocks attached. These will be attached to check valves that will be below water level and protected by revetment (stone) and new warning can buoys.

Shown are the 2 long sections of the 22 inch siphon pipes laying on the Dam Rd.

The 2 short sections in the foreground are the check valves. The maroon/reddish rings around the pipes are flanges. These are used to bolt two sections or in this case the check valves to the long strings of pipe next to them and bolt the other end of the check valves to the siphon pipe sections already installed and p

The upper valve house walls are poured. The large vertical black pipe riser is a cleanout for the collection pipes below the structure. If you look close, you can see the two 22 inch siphon pipes, white colored, entering the valve house base.

The shutoff/control vales were just delivered and will be installed in the near future to use to stop water from running through the siphon pipes that are

December 29, 2019

Pictured is a small test section of a wall using the concrete forms

that are yellow colored. These forms cause the concrete to look like the original stone that was used to build the spillway.

They are reusable if they separate from the cured concrete.

Concrete work is proceeding on the overflow spillway at a slow rate due to temperatures. Sections as they are poured are covered and heated to cure the concrete for 5-7 days.

Looking north from Dam Road, the first section of the spillway floor has been poured and covered with white tarps so it can be heated for proper curing.

Further down, (towards top of picture) are the yellow wall forms removed

The temporary diversion channel off of East Lake Road has been completed. Pictured is the access entrance constructed for the access road running back to the temporary.

The structure can be seen slightly in the distance appears white. Did not drive down for closer pictures due to mud/wet conditions but will try to get pictures from the state or will take some at a later date.

The temporary channe

1998 - 2001 Dam Repair Project

89 to 91 Dam Repair Project (docx)

Download